Our process engineering solutions are designed to enhance performance, reduce costs, and ensure compliance with global industry standards

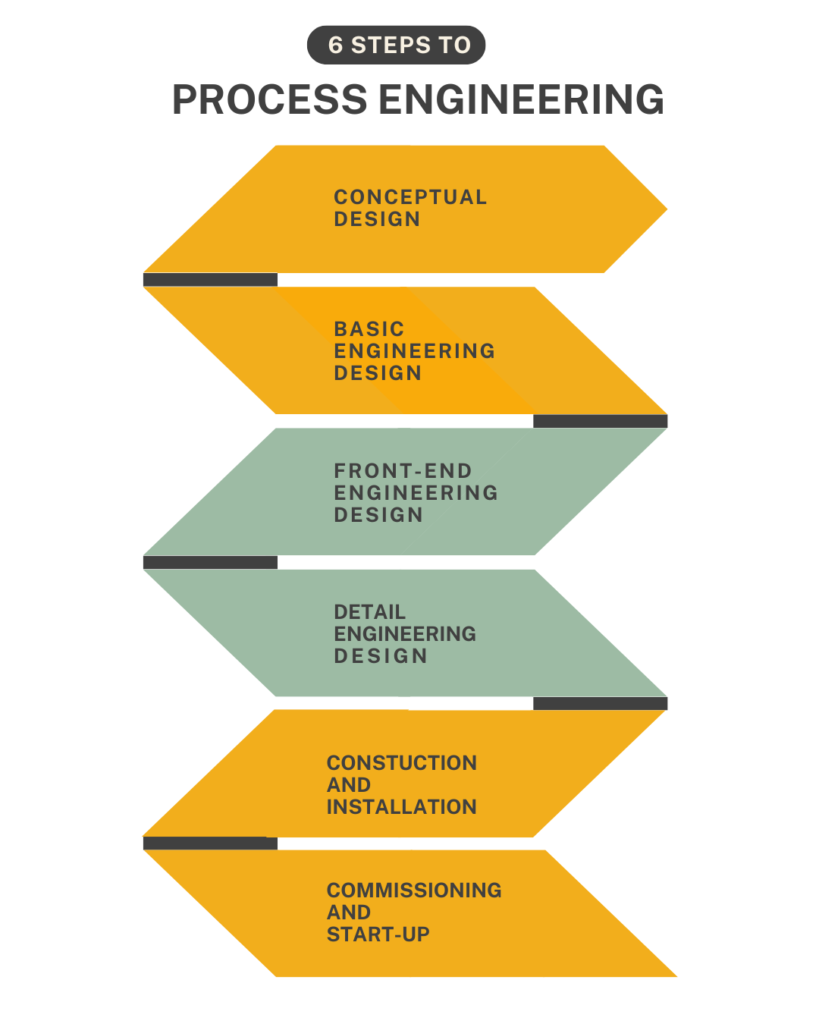

Process engineering, a critical activity within petrochemical projects, focusing on the design, optimization, and operation

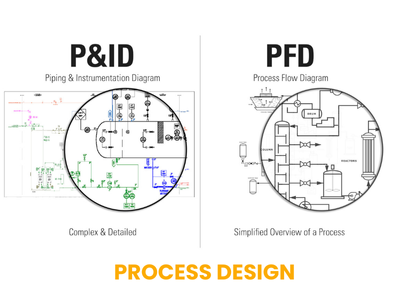

Our core activities in process engineering include: Process Design: Our engineers develop initial process concepts, including Block flow diagrams (BFDs), Process flow diagrams (PFDs), Piping and Instrumentation diagrams (P&IDs), which detail the piping, equipment, and instrumentation required for the process to ensure process efficiency and sustainability.